ActivateTM Yeast produces ethanol very efficiently in acidic/low pH conditions, under which no toxic microbes can survive, propagate, and/or contaminate the ethanol production process.

- Advanced Industrial Yeast Engineering and Enzyme Co-Products

Capable of co-fermenting nearly all xylosic (C5) and glucosic (C6) sugars, while expressing up to 80% of expensive glucoamylase enzyme required for conversion of starch to glucose

- Most Robust Yeast for Ethanol Production

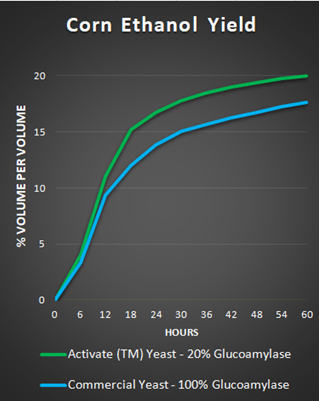

Patented gene integration technology provides a more stable microorganism that does not require antibiotics and can sustain ethanol concentrations up to 20% (vol/vol)

- Maximize Efficiency of Total Sugar Conversion to Ethanol

Cellulosic/Corn in 48-60 hours and Sugarcane in less than 24 hours

Benefits

- Increased ethanol yields and faster fermentation times

- Reduced capital investments required to expand ethanol production capacity

- Decreased enzymes costs and operational complexity

- Lower customer business risks via the capability to utilize multiple feedstocks

- Expand U.S. corn ethanol plants to co-produce cellulosic ethanol with corn ethanol